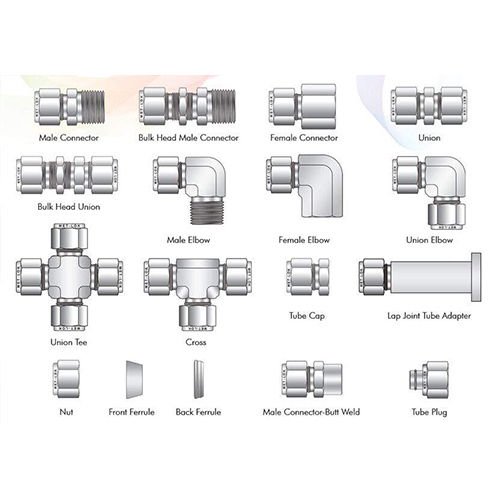

Instrument Fitting

Product Details:

- Product Type Instrument Fitting

- Material Stainless Steel

- Shape Customized

- Surface Treatment Polished

- Color Silver

- Warranty Yes

- Click to View more

Instrument Fitting Price And Quantity

- 1 Unit

- 250 INR/Unit

Instrument Fitting Product Specifications

- Stainless Steel

- Customized

- Yes

- Silver

- Polished

- Instrument Fitting

Instrument Fitting Trade Information

- 1000 Unit Per Week

- 2 Days

Product Description

Instrument Fittings are precision components designed for seamless connections in various industrial applications. They are available in a range of materials, including stainless steel, brass, and PTFE, and come in various configurations such as double ferrule, compression, cone and thread, and butt weld. These fittings ensure leak-free performance and are used in process control systems for fluid flow, pressure, and temperature measurement. They are available in different sizes and can be customized to meet specific industrial requirements. Instrument Fittings are essential for ensuring reliable and efficient fluid transmission and control in industries such as oil and gas, chemical processing, and power generation.

FAQ of Instrument Fittings

1. What are the main types of Instrument Fittings?

2. What materials are Instrument Fittings typically made from?

3. What industries commonly use Instrument Fittings?

4. How do Instrument Fittings ensure leak-tight performance?

5. What are some safety recommendations when using Instrument Fittings?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese